Cyanotype – the classic process

Cyanotype process – a modified extract from the book Blueprint to cyanotypes describing the classic or traditional cyanotype process.

Unlike photographs set in silver, like in black and white photography, cyanotypes are using a solution of iron compounds.

The photograph can be taken with a camera, like a digital camera, and the resulting photo turned into a negative that can be used to make a cyanotype.

The basic cyanotype recipe has not changed very much since Sir John Herschel introduced it in 1842. However, some advances have been made by Mike Ware in what is referred to as the New cyanotype process. Ware's cyanotype formula has less bleed, shorter exposure times and a longer density range than Herschel's, but it is also slightly more complicated to mix and uses more toxic chemicals.

The cyanotype process at a glance

The cyanotype process is simple. It can be done easily in a few steps:

Mixing chemicals

The cyanotype is made up of two simple solutions.

• Potassium ferricyanide and Ferric ammonium citrate (green) are mixed with water separately.

• The two solutions are then blended together in equal parts.

Preparing the canvas

• Paper, card, textiles or any other naturally absorbent material is coated with the solution and dried in the dark.

Printing the cyanotype

• Objects or negatives are placed on the material to make a print. The cyanotype is printed using UV light, such as the sun, a light box or a UV lamp.

Processing and drying

• After exposure the material is processed by simply rinsing it in water. A white print emerges on a blue background.

• The final print is dried and admired.

What you need

Before you start, get all the items you need together.

• 25 grams of Ferric ammonium citrate (green)

• 10 grams of Potassium ferricyanide

• Water (distilled if possible)

• Scale or measuring spoons

• Measuring jug

• 3 glass containers for mixing ingredients

• Plastic spoons

• Face mask (DIY style)

• Goggles

• Rubber gloves

• Apron or old shirt

• Newspaper to cover work surface

• Cleaning cloth

• Brushes or coating rod

• Clothes pegs (plastic)

• Washing line or rope (plastic)

• Art paper or fabric for coating

• Glass or a contact print frame

• Sunshine or a UV light source

Mixing chemicals

Cyanotype is a very simple process. It involves treating a surface with iron salts that reacts to UV light. Wear a face mask and rubber gloves when working with chemicals. In this case, Ammonium ferric citrate and Potassium ferricyanide. Two separate solutions are made and then equal quantities of each solution is mixed together in a third container.

The formula

This recipe makes approximately 50 8×10 inch prints. The cyanotype is made up of two simple solutions:

• Solution A: 25 grams Ferric ammonium citrate (green) and 100 ml. water.

• Solution B: 10 grams Potassium ferricyanide and 100 ml. water.

1

Mixing the chemicals

Dissolve the chemicals in water to make two separate solutions. Add Ammonium ferric citrate to water into one container and Potassium ferricyanide to water in another. Stir with a plastic spoon until the chemicals dissolve. Mix equal quantities of each solution together in a third container. Unused solutions can be stored separately in brown bottles away from light, but will not last very long once they have been mixed. Dispose of any unused chemicals in a sensible and environmentally friendly way!

Your work area

Your floors, carpets, walls, work surfaces, clothes and skin can be stained by the chemicals. Cover all possible areas, use rubber gloves and an apron or an old shirt to work in. If you have the space, choose an area where you can spread out. Ordinary light bulbs or tungsten light is safe to use, but UV light will affect your prints. Some fluorescent lighting may also affect your prints.

2

Preparing the canvas

Using a brush, simply paint the chemicals onto the material. Paper, card, textiles or any natural material can be used to print on. Decide how big your print is going to be, and cut your material to size. Make sure your working area is dimly lit, or lit with a low-level tungsten bulb. Once the material is coated, leave it to dry in the dark.

3

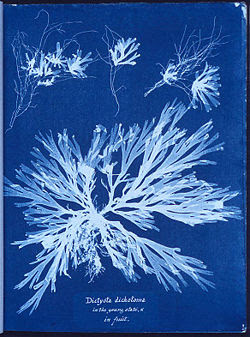

Printing the cyanotype

Print a cyanotype by placing your negative (to reproduce a photograph) or object (to make a photogram) in contact with your coated paper or fabric. Sandwich it with a piece of glass. Expose the sandwich to UV light. Natural sunlight is the traditional light source, but UV lamps can also be used. A photogram can also be made by placing items on the surface. Plants, decorative items or other objects can be used to create silhouettes or interesting shapes. Exposure times can vary from a few minutes to several hours, depending on how strong your lightsource is or the season where you are printing.

4

Processing and drying

When the print has been exposed, process your print by rinsing it in cold water. The wash also removes any unexposed chemicals. Wash for at least 5 minutes, until all chemicals are removed and the water runs clear. Oxidation is also hastened this way – bringing out the blue color. The final print can now be hung to dry and be admired.

Good luck!

No comments:

Post a Comment